Manufacturing

We taken initiative that aligns with the ambitious Saudi Vision 20230 and to explore opportunities into manufacturing. Saudi Vision 2030 aims to diversify the Kingdom’s economy by fostering the growth of various sectors, including manufacturing.

Our state-of-the-art facilities and experts team enable us to deliver reliable and innovative products that enhance operational efficiency.

Our new manufacturing facility will enable us to produce high quality Engineered with advanced signal processing technology locally, create job opportunities and enhance our competitiveness in both Saudi & Middle East markets.

Fluenta flare gas measurement solutions not only ensure your regulatory compliance, they help you explore alternative revenue streams and build a path towards Net Zero.

FLUENT IN FLARE GAS MEASUREMENT SINCE 1985

Ultrasonic measurement of flare gas is our core expertise and, as the world moves towards net zero, we're applying it to help not only reduce flaring as a whole, but also to measure and ultimately control emissions.

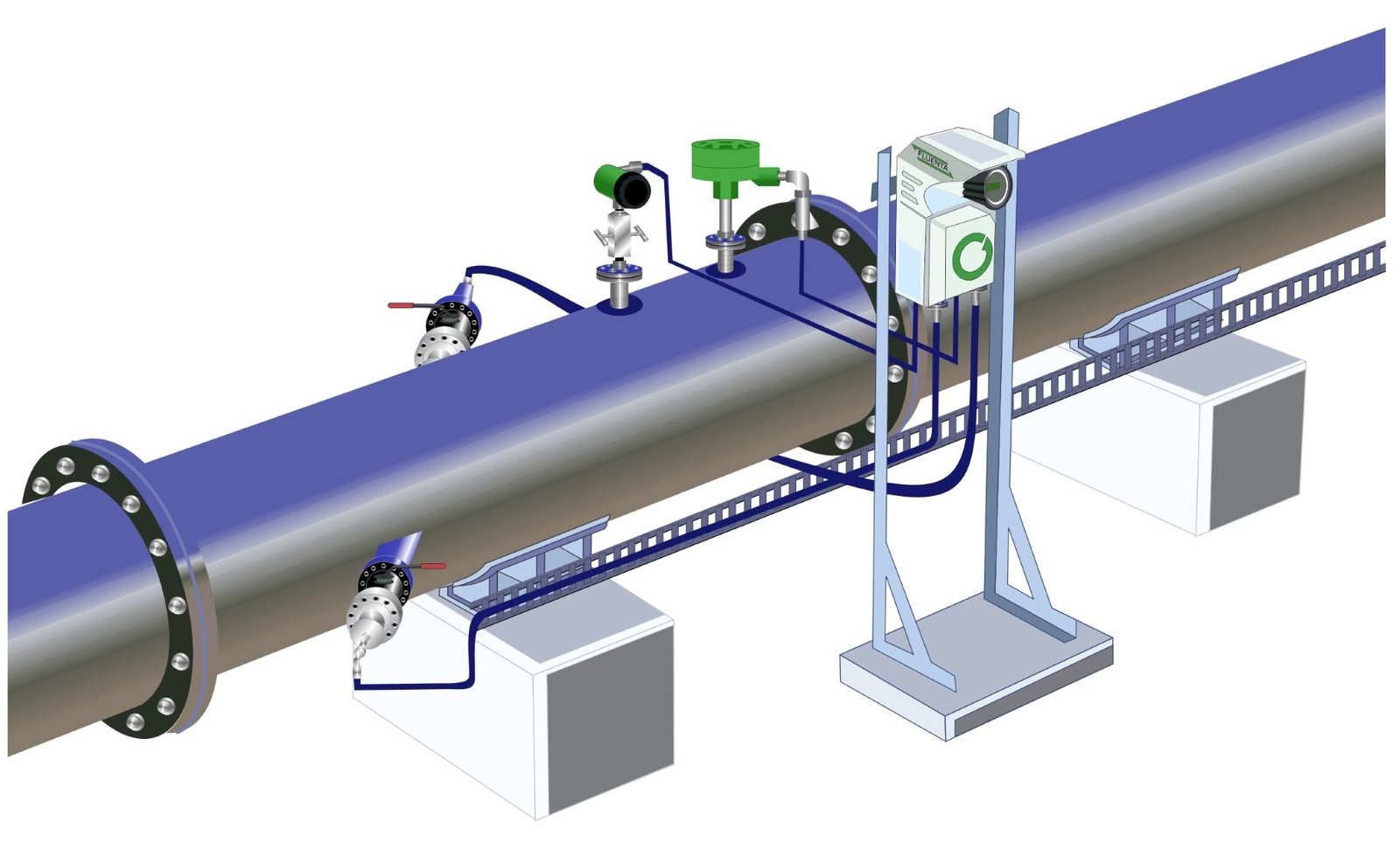

FGM 160 FIELD COMPUTER

The Fluenta FGM 160 Field Computer stands as a

benchmark in flare gas measurement, offering unmatched accuracy and reliability.

Engineered with advanced signal processing technology, this ultrasonic flow meter could achieve an accuracy of ±0.75% across pipe diameters ranging from 6 to 100 inches, ensuring dependable operations.

Central to Fluenta’s flare gas measurement solutions, the FGM 160 supports the oil and gas, petrochemicals, and LNG industries in accurately monitoring flare gas flow. It’s not just a tool for measurement but a means to achieve regulatory compliance and meet environmental responsibilities.

The FGM 160 blends accurate measurement with ease of use, offering a reliable solution for diverse industry needs.

Optimized for high levels of CH4 and CO2.

Operating temperature of -200 °C to +250 °C

Capable of handling extremely high temperatures Operating temperature: -40 °C to +350 °C

Optimized for handling cryogenic applications, making it ideal for the LNG and gas liquefaction

Operating temperature of -200 °C to +250 °C

Standard Sensor Technology

Operational temperature: -40°C to 145°C

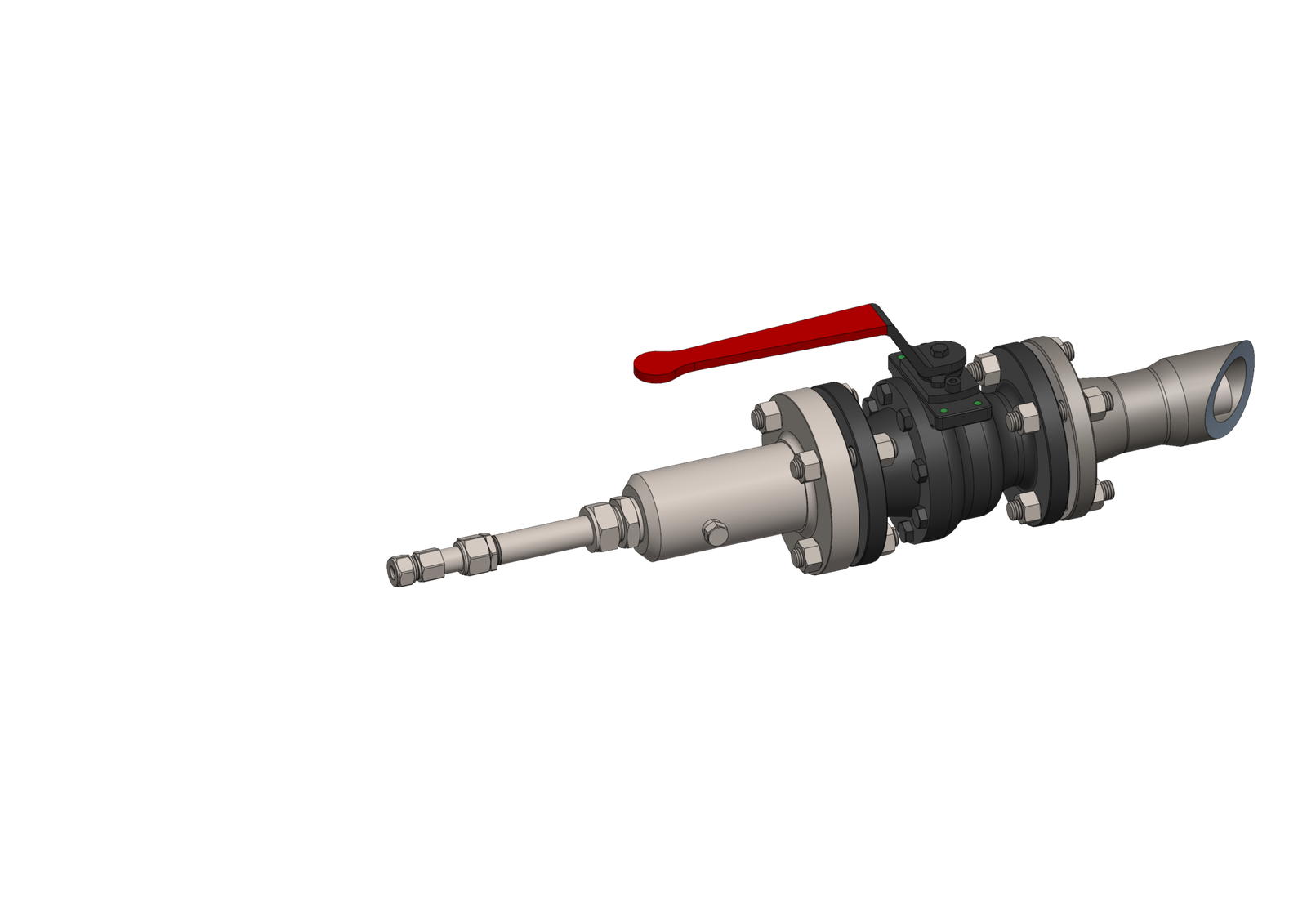

TRANSDUCERS

- Made out of Titanium/SS316

- IECEx, ATEX, NRTL(CSA), TR-CU, INMETRO certified

- Zone 0 certified with safety class Ex IIC T4-T6

- Non-intrusive installation

- Suitable for pipe size from 6” to 100”

- Accuracy up to 0.75% in dual path condition

FIELD COMPUTER

- The only Field Computer certified for Zone 1 – intrinsically safe

- IECEx, ATEX, NRTL (CSA), TR-CU, INMETRO certified

- Ex de [ia] IIC T6

- 24V DC power supply

- Foundation Fieldbus, HART, HART 5,6 or HART 7 outputs